TURNING FARM SLURRY INTO HYGIENIC BEDDING

GOODWIN’S FARM IN SUSSEX, AN 800-acre unit that is home to 700 cows, wanted a cattle bedding alternative that would utilise its slurry and reduce the amount held in on-site storage. This would

not only free up space on the farm but also reduce the risk of any environmental damage occurring from leaks or the production of harmful ammonia gases.

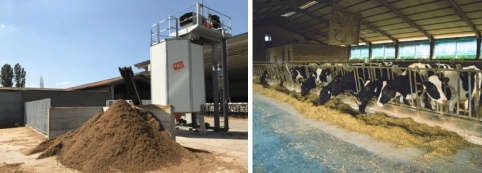

An HBC Biocell, a complete solution that turns slurry into a hygienic bedding alternative for cattle, was installed on the farm by T-T Pumps. Complete with all of the equipment needed for effective slurry handling – chopper pumps, separators, hoses, level control, control panel, and more – the biocell separates and pasteurises the solid part of slurry, meaning it is mainly liquid slurry being sent to storage.

This slurry separation reduces the need for on-site storage and increases the quality of both the solid and liquid slurry content – the solids are utilised as a hygienic bedding alternative, and the liquids can be used as an environmentally friendly fertiliser, recycling the slurry’s nutrient-content for crop growth.

Commenting on the installation, a representative from Goodwin’s Farm said: “We thought that the principle of pasteurised bedding was a very positive one, with 60% of our cubicles on sawdust

and mattresses and the other 40% deep lying sand cubicles. We liked the idea of pasteurised bedding and the benefts it can bring as well as the cost savings.

“It has been a constant learning process from day one, in terms of how long to run the machine, the importance of using only freshly produced bedding for that day, how often to bed up, how much lime to use and how often to sweep the cubicles. We fnally feel that we have the right routine for the bedding.

“What goes into the tower is now far more liquid and easier to pump. We have saved directly in bedding costs as well.”

As well as the cost-saving benefts and environmental improvements to its slurry handling, the farm also saw a 30% reduction in slurry entering its slurry tower.

Back to Latest News

3.png&w=170&h=170)

1.png&w=170&h=170)

2.jpg&w=170&h=170)