How does MEI affect me

When pumps account for half of a typical industrial plant’s running costs and studies show the vast majority are running inefficiently, there are opportunities to reduce running costs and carbon footprint whilst maximising uptime and profitability. James Dashwood, Managing Director at Crest Pumps, explains how focusing on the minimum efficiency index of pumps and their wider systems can help.

Because of the significant potential for energy savings in pumping systems, EU Regulation EU 547/2012 sets out minimum efficiency requirements for water pumps, expressed by the Minimum Efficiency Index (MEI), a ratio of the actual efficiency of a pump to the best efficiency point (BEP) for that pump type. The MEI rating considers the hydraulic efficiency of the pump, the motor efficiency, and the power factor of the motor. An MEI of 1.0 indicates that the pump is operating at its highest possible efficiency, so the higher the MEI rating, the more efficient it is.

In 2009, an EU commission mapped out all the pumps available on the market and measured their efficiency. Based on this, they decided that the least efficient 10% of pumps would be removed, meaning pumps with an MEI of 0.1 or less. Since January 1, 2015, all pumps must operate with an MEI rating of more than or equal to 0.4. Any pump with an MEI ≥0.7 exceeds the highest efficiency standard set.

What are the benefits of a pump with an MEI greater than 0.7? The first benefit is lower operating costs. A pump with a higher MEI will consume less power, which translates into lower operating costs resulting in significant cost savings over the pump’s lifetime. A further benefit is a reduced carbon footprint. An energy-efficient pump will also have a lower carbon footprint, helping users achieve their corporate sustainability goals. A pump with a higher MEI will also have improved reliability, resulting in less downtime and reduced maintenance costs.

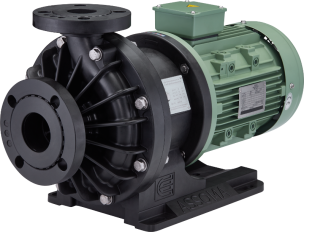

This Regulation only applies to rotodynamic water pumps for pumping clean water and includes end suction and vertical and horizontal multistage pumps. Even though MEI doesn’t currently include chemical-resistant pumps, the Crest Assoma AVF-X range has been developed to be one of the first magnetic drive thermoplastic pumps to exceed the highest standard set above 0.7. Choosing any pump that exceeds this standard means you can rest assured knowing you are using one of the most energy-efficient pumps available and benefiting from exceptional energy savings in your production processes whilst reducing your overall carbon footprint.

The bigger picture

The pump, however, is just one element of a pumping system. The Extended Product Approach (EPA), developed by Europump and supported by the British Pump Manufacturers’ Association, calculates the Energy Efficiency Index (EEI) of an Extended Product (EP) – which covers the pump, its drive motor and a variable speed drive if used – and incorporates load profiles and the control method. The EEI is derived from the total efficiency of the pump unit at different loads. This system approach focuses on optimising the energy consumption of the pump unit in the actual flow system it is intended to operate and to ensure that only the electrical energy necessary to achieve the required performance is used.

When looking solely at the pump, an MEI rating of 0.4 can save 5TWh a year in the EU, but with the extended product approach, there is the potential to save 59TWh annually. So, taking a wider perspective can create much more significant energy savings and all of these worldwide savings start with the pumps in your factory.

Today, an ideal pump set up will consist of a pump with an MEI greater than 0.7, an IE4 (or even IE5) motor, plus an inverter. But with a higher initial cost outlay, you want to ensure you get an adequate return on investment. For peace of mind, investigate the entire Life Cycle Cost (a helpful comparison tool can be found at bit.ly/CrestLCC), which considers every area of cost when it comes to the operation of a pump over its estimated life. You can then compare the two and find out how long the payback will be for the higher efficiency option compared to the higher running costs of the cheaper pump. www.crestpumps.co.uk

Back to Latest News

3.png&w=170&h=170)

2.jpg&w=170&h=170)

1.png&w=170&h=170)