ACCURATE, LOW FLOW DOSING AND TRANSFER

NOV has expanded the availability of its Low Flow Metering Range Pump, which offers optimised process times, lower operations costs, and minimised downtime.

NOV has expanded the availability of its Low Flow Metering Range Pump, which offers optimised process times, lower operations costs, and minimised downtime.

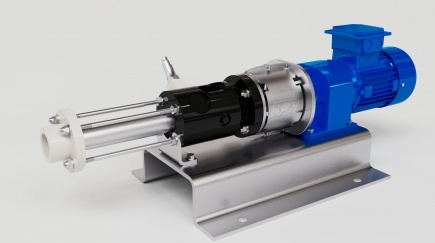

Designed for use where accurate, low flow dosing or transfer pumps are required for either intermittent or continuous dosing, the pump has a high tolerance to aggressive chemicals (0-14PH).

The Low Flow Metering Range Pump includes enhanced element offerings with improved precision metering control technology, reduced break-out torque, and good slow-speed performance. These elements help to expand the scope of metering applications while still supplying each fluid with a smooth, pulsation-free flow.

The advantages of the Low Flow Metering Range Pump include the ability to handle abrasives, corrosives, solids in suspension, and viscous fluids. The pump can work with pressures up to 300 psi or 24 bar, and the pressure capability is independent of speed. It is self-priming and has a high suction lift capability with a low shear pumping action and no valves to clog, stick, or vapour lock. The design is also compatible with integral variable frequency drives and motor controls, supporting low power consumption and operating costs.

The use of different stator materials enables the pump to be used for a wide range of applications and products, including acids and alkalis, wastewater chemical injection, chemical processing for various industries and the pharmaceutical industry. Constructed of the most dependable materials, most of the pump components are supplied in stainless steel. The suction chamber is manufactured in high-density polyethylene, while the end cover and mechanical seal housing are made of polyvinylidene fluoride. For severe chemical environments, internal pump components can be supplied in Hastelloy.

Fully sealed joints maximise life and minimise downtime, while packing, single, and double mechanical seals are available in various materials to support the most corrosive applications.

Gearbox and motor options include close coupled, long coupled, synchronous speed motor, fixed speed gearbox, and frequency inverter.

Back to Latest News

2.jpg&w=170&h=170)

3.png&w=170&h=170)

1.png&w=170&h=170)