SCALABLE HIGH-PRESSURE TURNKEY CLEANING SYSTEMS

For wash down applications in the food, beverage and associated industries, high pressure is the key to efficiency and performance. In addition, the ability to regulate that pressure and the flow, as demand requires, enables operators to complete the cleansing with less water and power, hence less cost.

For wash down applications in the food, beverage and associated industries, high pressure is the key to efficiency and performance. In addition, the ability to regulate that pressure and the flow, as demand requires, enables operators to complete the cleansing with less water and power, hence less cost.

Many plants need high-pressure wash down capabilities for cleansing and sanitation plus odour control, dust suppression and scale removal. Scalability is the key as often single pumps cannot meet the demand. SundWASH systems have the ability to add additional pumps as operations expand and/or require more pressure, for example, for additional spray wands.

Also, the software, unlike other systems, can idle the pump (or pumps) during periods of low demand to save energy. For example, with a two pump system, one might be sufficient most of the day, but at the end of the day or end of a shift, all spray wands may be used at once to clean up and prepare for the next day’s production. The pumps can also be powered up or down during periods of peak demand as required.

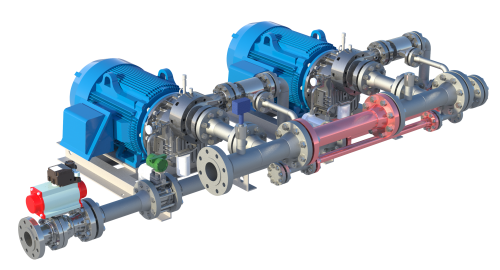

SundWASH high-pressure systems are complete packages comprising all of the component parts for a centralised cleaning system. The modular layout, with SundWASH pumps being arranged in parallel, offers a small footprint, with additional wash down modules easily added to accommodate plant growth or changing circumstances.

The high pressures produced increase efficiency and enable operators to complete the wash down with less water. A SundWASH system can save substantial quantities of water in a single day or week, often meaning that the payback on a SundWASH system is less than the first year of operation.

Easy to remove cartridge assemblies, which can be repaired in place by just one person within one hour and with one standard tool, make for further efficiencies. avtpump.com

Back to Latest News

3.png&w=170&h=170)

1.png&w=170&h=170)

2.jpg&w=170&h=170)